Transmission oils for motor vehicles by ADDINOL

ADDINOL automotive transmission oils offer a reliable solution for almost any application. These include high-load hypoid transmission, synchronised and unsynchronised manual and steering transmission, transmissions for hybrid cars, electric cars as well as distribution transmission of car, truck (e.g. hypoid transmissions), tractor, forestry and construction machines as well as stationary plant.

Transmission oils from ADDINOL can fulfil even the most extreme requirements and specifications. They offer effective protection against wear and even ideal friction behaviour for cold starts. In addition, our transmission oils provide optimum viscosity, at both low and high temperatures. For example, our Multi Transmission Fluid 75 W 80 or our transmission oils of the GH series ensure the maximum lifetime for your transmission.

Transmission oils by viscosity

If you already know which viscosity class your transmission oil should have, you can discover the categories in detail.

Transmission oils by OEM

We have compiled the approved ADDINOL transmission oils and prepared them for some OEMs.

Your benefits at a glance:

- Excellent flow properties

- Optimised friction behaviour

- Suitable for the highest loads at high and low temperatures

- Reliable protection against wear and corrosion for the longest transmission lifetime

- Increased oil changing intervals

- Maximum energy efficiency through safe and reliable lubrication

- Excellent, personal service thanks to our Application Technology

Information about transmission oils

Requirements for transmission oils

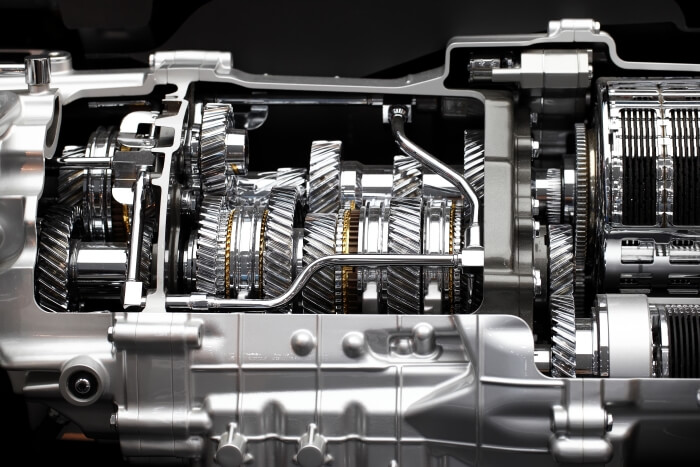

The lubrication of a transmission places special demands on the lubricant used. When loaded tooth flanks mesh together, a high pressure acts on the lubricant, which must constantly form a lubricating film in order to avoid direct contact of these friction partners. If the metal surfaces of the tooth flanks meet directly, a friction condition (mixed friction) could occur in which the tooth surfaces may be damaged severely by increased wear. This could result in damage that might lead to the failure of a gearbox. Transmission oils shall prevent this.

The most important requirements for transmission oils are:

- Lubrication of the friction partners

- Compatibility with sealing materials

- Optimised friction behaviour for shifting operations

- Cooling of the transmission by heat transfer to the housing

- Protection against corrosion, wear, deposits and foam

- Optimised viscosity for high temperature and low temperature flowability

- Resistance to ageing due to oxidation and temperature variations

Transmission oils are required in almost all motor vehicles. There are transmission oils for cars, trucks, tractors and motorcycles. In many vehicles, you might find several different types of transmission. Manual transmissions, differentials, or axle drives – each requires special lubricants. In addition, there is the distinction between lubricants for manual transmissions and lubricants for different types of automatic transmissions. This also becomes relevant if you want to top up or change transmission oil yourself.

Composition of transmission oils

Like engine oils, transmission oils consist of base oils (mineral or synthetic) and additive combinations tailored to the particular demands in the field. The manufacturing process of a transmission oil is basically the same as that of other automotive oils. In comparison to engine oils, however, the additive content can be significantly higher, since transmission oils in commercial vehicles are intended to be changed at intervals of up to 750,000 km.

The application of EP additives is very important for transmission oils. They prevent scuffing of the metal-to-metal friction partners. Axle drives require a high portion of EP additives, which usually consist of phosphorus and sulphur components. However, sulphur components can cause corrosion and ageing problems, so corrosion inhibitors and antioxidants must be added as compensation. A simple example like this already shows that additives in lubricants have to be matched carefully to each other. This requires experience and tests by the lubricant manufacturer in order to find an optimal interaction of the additives in the oil. However, overdosing due to the addition of additives to finished fluids by end users can quickly reverse the advantages of a specifically tailored transmission oil.

In addition, transmission oils have to resist high and low temperatures, prevent corrosion and remove impurities from the oil circuit.

Important additives in transmission oils are:

- EP additives (Extreme Pressure - to protect against scuffing)

- AW additives (Anti Wear - to protect against wear)

- Friction modifier (not always the lowest, but an optimal friction coefficient is important)

- Defoamer (reduction of foam formation)

- Corrosion inhibitors (reduction of corrosion and neutralisation of acids)

- Viscosity-Index improver (optimisation of viscosity-temperature behaviour)

- Pour Point Depressant (improvement of low temperature behaviour)

- Antioxidants (reduction of oil ageing)

Automatic Transmission Fluids - ATFs

In Europe, about 35% of all passenger cars and more than 50% worldwide are equipped with automatic transmissions with an upward trend. Modern automatic transmissions are efficient and sporty - largely independent of the design principle. A distinction is made here between three systems, each of which has its own advantages and disadvantages and puts special demands on the fluids. There are torque converter automatic transmissions (AT - most widely used), dual clutch transmissions (DCT - also common and increasingly popular) and continuously variable transmissions (CVT - small market share, more popular in Asia). Learn more about Automatic Transmission Fluids here.

Are you interested in our transmission oils? Find a sales partner near you.