ADDINOL industrial lubricants set new standards

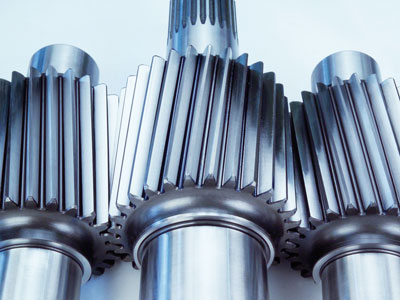

ADDINOL offers high-performance lubricants for almost every industrial application. With innovative products, such as the high-performance gear oil ADDINOL Eco Gear or the ADDINOL gas engine oils, which are used in communal heating / power stations with natural and special gases, ADDINOL sets new standards in tribology. Hydraulic fluids, corrosion protection and compressor oils for the construction industry or slipway and metal processing oils for the machining industry round off the product range in this area.

Applications for industrial lubricants

Unlike automotive lubricants, which are used to lubricate vehicles, industrial lubricants are primarily intended for use in stationary installations. Within industrial lubricants, a distinction is made between liquid lubricants (oils) and solid lubricants (greases and pastes).

| Industrial lubricant | Fields of application |

|---|---|

| Gas engine oils | Combined heat and power plants, biogas plants |

| Guideway oils | Horizontal and vertical slideways and guideways |

| Hydraulic Oils | Tractors, trucks, excavators, presses and injection molding machines |

| Gear oils | Steel industry, mining rails, wind turbines |

| Chain lubricants | Conveyor chains, conveyor rollers, drive belts, continuous ovens, press lines |

| Corrosion protection oils | Storage of components and tools, transport of finished products |

| Lubricants for food and beverage industry | Food grade lubricants for gearboxes, chains and hydraulics in food and pharmaceutical industries |

| Oil for metal working | Machining and non-cutting forming of ferrous and non-ferrous materials |

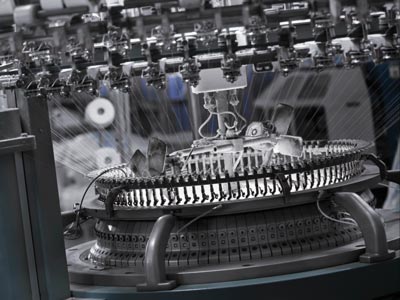

| Textile machine oils | Lubrication of needles and blanks in circular and flat knitting machines, general use in all stages of textile production |

| Turbine oils | Use in water, gas and steam turbines, turbocompressors and transmission compressors |

| Greases ans pastes | Greasing of wheel bearings, window regulators and sunroofs on the car, use in industrial installations on slideways and rolling bearings |

| Compressor oils | Screw, rotary and reciprocating compressors |

| Heat-transfer oils | Wood processing, film production, paper industry |

Viscosity classes of industrial lubricants according to ISO VG

The viscosity classes of ISO VG (International Organization for Standardization Viscosity Grade) apply to all lubricating oils that are not part of the engine and transmission oils for motor vehicles. There are 18 viscosity classes defined by a minimum and maximum kinematic viscosity (expressed in mm² / s) at 40 ° C. This corresponds to a deviation of + - 10% from the mid-point viscosity. The viscosity classes according to ISO VG range from 2 (thin liquid) to 1500 (viscous). Since the industrial machines are usually operated at a constant temperature, the viscosity index (VI) is hardly relevant for industrial lubricants. Multi-grade oils are only needed in some hydraulic systems.

| ISO VG | Mid-point viscosity mm²/s 40°C | Kin. viscosity min. mm²/s 40°C | Kin. viscosity max. mm²/s 40°C |

|---|---|---|---|

| 2 | 2,2 | 1,98 | 2,42 |

| 3 | 3,2 | 2,88 | 3,52 |

| 5 | 4,6 | 4,14 | 5,06 |

| 7 | 6,8 | 6,12 | 7,48 |

| 10 | 10 | 9 | 11 |

| 15 | 15 | 13,5 | 16,5 |

| 22 | 22 | 19,8 | 24,2 |

| 32 | 32 | 28,8 | 35,2 |

| 46 | 46 | 41,4 | 50,6 |

| 68 | 68 | 61,2 | 74,8 |

| 100 | 100 | 90 | 110 |

| 150 | 150 | 135 | 165 |

| 220 | 220 | 198 | 242 |

| 320 | 320 | 288 | 352 |

| 460 | 460 | 414 | 506 |

| 680 | 680 | 612 | 748 |

| 1000 | 1000 | 900 | 1100 |

| 1500 | 1500 | 1350 | 1650 |

Are you interested in our industrial lubricants? Find a sales partner near you.