ADDINOL Greases and Pastes

ADDINOL offers a wide range of high-performance greases and pastes suitable for use under various operating conditions in automotive and industrial applications. In addition to the typical application area of roller and plain bearing lubrication, the ADDINOL range also includes greases for the lubrication of open and closed gearboxes, wheel flanges of rail vehicles, wire ropes and elastomeric sealing materials.

The product range of ADDINOL Greases and Pastes

- Multi-purpose greases without additional solid lubricants

- Multi-purpose greases with solid lubricant additives like adhesive lubricants

- Liquid greases without additional solid lubricants

- Liquid greases with solid lubricants

- Lubricating greases for fast rotating bearings and cryogenic applications

- Synthetic greases for high temperature applications

- Greases for special applications (e.g. silicone greases)

- Lubricating greases for the food industry

- Quickly biodegradable lubricating greases

- Pastes

You will find an overview of lubricating greases and pastes in our Product-Finder.

Your benefits at a glance:

- Reliable wear and corrosion protection of machine elements even under demanding operating conditions such as extreme operating temperatures, shock loads, vibrations, high humidity and dusty environments.

- High economic efficiency due to optimised energy efficiency and ageing stability

- Consistently high product quality on the basis of selected base components and high-performance additives in conjunction with sophisticated in-house quality testing during the manufacturing process

- Expert and individual advice from our application technology department

Information about lubricating greases

Composition of lubricating greases

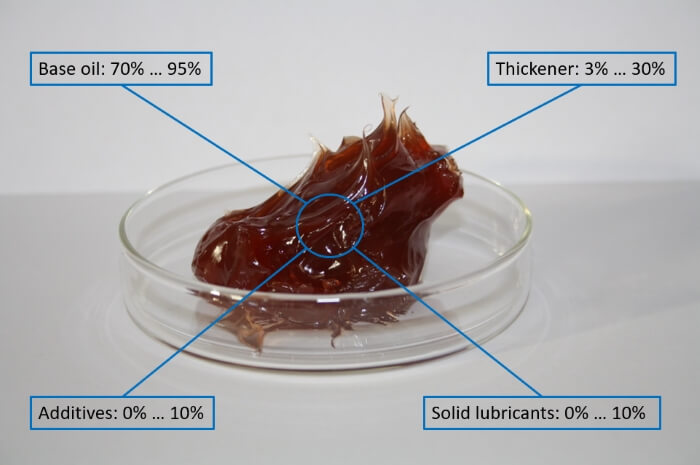

Lubricating greases are semi-liquid to solid lubricants which are produced by introducing a suitable thickening agent into a liquid base oil. Certain properties of a lubricating grease can also be specifically improved by adding additives and solid lubricants. Compared to lubricating oils, lubricating greases are more complex lubricants in terms of their basic structure. The performance (e.g. dropping point) of a lubricating grease is influenced by the properties of all its individual components, such as base oil, thickener, additives and solid lubricants. The multitude of possible combinations of different base oils in different viscosities with different thickener types and different additives allows the production of a large number of different lubricating greases.

The structure of lubricating pastes is basically similar to the structure of lubricating greases. In contrast to greases, however, lubricating pastes always contain a high proportion of solid lubricants. Although many lubricating pastes contain thickener components which are also used in lubricating greases, the use of a thickener in the production of a paste can be dispensed with by using certain types of solid lubricant. The consistency of such thickener-free lubricating pastes is then achieved exclusively by the amount of solid lubricant contained.

The main component of a lubricating grease can be considered to be the base oil contained, the proportion of which in the final end product is typically in the range between 70% and 95%.

Depending on the thickener type selected and the desired consistency of the grease (which in turn is characterized by NLGI classes), lubricating greases contain a proportion of thickeners in the range of 3% to 30%. The proportion of added additives can be up to 10%. If a lubricating grease contains solid lubricants, their proportion is a maximum of about 10%.

Consistent lubricants with solid lubricant contents greater than 40% are classified as pastes. For fat-like special products with a solid lubricant content between 10% and 40%, the term grease paste is commonly used.

Base oils for lubricating greases

The base oil as the main component of a lubricating grease has a significant influence on its lubricating and service properties. The thermal and oxidative resistance of the base oil influences the usable temperature range and the ageing stability of the grease. Lubricating greases for low-temperature applications contain selected base oils with a particularly low pour point. The viscosity and viscosity-temperature behaviour of the base oil are important influencing factors for the formation of load-bearing lubricating films and the torque behaviour of the grease under the respective operating conditions. In addition, compatibility with elastomer sealing materials also depends on the base oil selected.

The following base oil types can be used in lubricating greases:

- Mineral oils (naphthenic oils, paraffinic oils, aromatic oils, white oils)

- Synthetic oils (polyalphaolefin, ester, polyalkylene glycol, polyisobutylene, silicone oil, perfluoropolyether)

- Vegetable oils (rapeseed oil)

Base oil mixtures of mineral oils with synthetic oils can also be used for fat production, which ultimately results in semi-synthetic products.

Thickening agent

The thickening agent used influences the texture of a grease, its mechanical stability, its resistance to media (e.g. water, solvents) and last but not least its temperature range. The most frequently used thickeners can be classified as soaps. Soaps are metal salts of fatty acids (aliphatic monocarboxylic acids) formed in a chemical reaction of these fatty acids with a metal hydroxide. The hydroxides of the metals sodium, lithium, calcium, barium and aluminium are mainly used for the production of lubricating greases. A distinction is also made between simple soaps, mixed soaps and complex soaps. If a fatty acid is reacted with a single metal hydroxide, a simple soap is obtained. If two different metal hydroxides are used simultaneously, a mixed soap is formed (e.g. lithium calcium soap). Single and mixed soaps contain only the fatty acids mentioned above. In contrast, complex soaps are produced by reacting a corresponding metal hydroxide with a fatty acid and a second acid that does not belong to the fatty acid group. In addition to the soaps described, other organic and inorganic compounds can also be used as thickeners. Frequently used organic non-soap thickeners include polyurea and polytetrafluoroethylene (PTFE). Frequently used inorganic non-soap thickeners include bentonite and silica gel.

NLGI classes

Depending on the amount of thickener added, greases can be produced in various consistencies. The consistencies can be classified into nine NLGI classes by a measuring method of the National Lubricating Grease Institute (NLGI). The measuring method is known as cone penetration. It determines the penetration depth of a cone into a grease sample (in 0.1 mm) under standardized test conditions. The deeper the cone penetrates and the higher the value in 0.1 mm, the softer the grease is.

Additives in lubricating greases

By adding additives, the service properties of lubricating greases can be optimised, particularly with regard to adhesion, ageing stability, corrosion protection, wear protection and load carrying capacity.

The following additive types are currently used in lubricating greases:

- Oxidation inhibitors to improve ageing stability

- Corrosion inhibitors

- Pourpoint depressants for improving low temperature properties

- Additives to improve the adhesive strength

- AW additives (Anti-Wear additives)

- EP additives (Extreme-Pressure additives)

DIN standards for lubricating greases

There are two essential DIN standards for lubricating greases, which predefine basic classifications and requirements:

- DIN 51825: Lubricants - Lubricating greases K - Classification and requirements

- DIN 51826: Lubricants - Lubricating greases G - Classification and requirements

The DIN 51825 standard applies to lubricating greases for the lubrication of rolling bearings, plain bearings and sliding surfaces in NLGI classes 1 to 4. The DIN 51826 standard applies to lubricating greases for the lubrication of drive technology elements (in particular closed gears) in NLGI classes 000 to 2.

In accordance with DIN 51502 (which is also considered in the above-mentioned standards DIN 51825 and DIN 51826), greases can also be marked according to a specified set of rules, which is based on a sequence of code letters and code numbers. A lubricating grease K (according to DIN 51825) with additives of EP additives and solid lubricants, which contains a base oil of synthetic hydrocarbons, has a consistency in NLGI class 2 and an operating temperature range from -30°C to +140°C, would have to be marked with "KPFHC 2 N-30" according to this code.

The following table shows a detailed overview of the code letters and code numbers defined according to DIN 51502 for the identification of greases:

| Code letter / Product specification | Possible code letters and code numbers acc. to DIN 51502 | Example marking KPFHC 2 N-30 |

| Code letter Grease type | K ... Grease for rolling bearings, plain bearings and sliding surfaces according to DIN 51825 G ... Grease for closed gears according to DIN 51826 OG ... Grease for open gears M ... Grease for plain bearings and seals | K |

| Additional letter Additive | P ... addition of EP additives F ... addition of solid lubricants | PF |

| Additional letter Basic oil type | Without ... Mineral oils HC ... Synthetic hydrocarbons PG ... Polyglycols E ... Organic esters PH ... Phosphoric acid ester FK ... Perfluorinated oils SI ... Silicone oils X ... Others | HC |

| NLGI Class | The code number corresponds to the numerical value of the NLGI class | 2 |

| Upper operating temperature and water resistance | C-U ... Upper operating temperature in °C Water resistance according to DIN 51807 | N |

| Lower operating temperature in °C | The code number corresponds to the numerical value of the lower operating temperature | -30 |

More precise breakdown of operating temperature and water resistance:

| Code letter | Upper operating temperature | Water resistance according to DIN 51807 |

| C | +60°C | 0-40 or 1-40 |

| D | +60°C | 2-40 or 3-40 |

| E | +80°C | 0-40 or 1-40 |

| F | +80°C | 2-40 or 3-40 |

| G | +100°C | 0-90 or 1-90 |

| H | +100°C | 2-90 or 3-90 |

| K | +120°C | 0-90 or 1-90 |

| M | +120°C | 2-90 or 3-90 |

| N | +140°C | In agreement |

| P | +160°C | |

| R | +180°C | |

| S | +200°C | |

| T | +220°C | |

| U | > 220°C |

Use of lubricating greases

Compared to lubricating oils, lubricating greases are characterized by higher adhesion and lower flowability. They thus remain more easily at lubrication points which cannot be sealed in a suitable manner due to a high design effort in order to prevent the flow away of alternatively usable lubricating oils from the lubrication point. Rolling bearing lubrication is one of the main areas of application for lubricating greases. In grease-lubricated rolling bearings, the grease used performs an additional sealing function and protects the bearing against environmental influences such as high dust loads, high humidity or splashing water. In contrast to lubricating oils, which can be circulated in oil circulation systems and can therefore perform transport functions in addition to their primary function as a lubricant, lubricating greases are not suitable for removing heat, impurities or wear particles of comparable size from the lubrication point.

Are you interested in our greases? Find a sales partner near you.