Solid lubricants

Solid lubricants are solid substances that can effectively separate the surfaces of two friction partners and thus reduce both friction and wear. Typical examples of solid lubricants are graphite, molybdenum sulphide, soft metals (aluminium, copper, etc.) and plastics such as polytetrafluoroethylene (PTFE). The most used solid lubricants can be divided into three main groups, considering their different mechanisms of action.

Types of solid lubricants

The effectiveness of a first main group of solid lubricants can mainly be attributed to their special structural design. This group of solid lubricants is often categorised with the term "structurally effective solid lubricants". The essential feature of these structurally effective solid lubricants is a layered lattice structure in which the individual atoms are arranged in layers (also called lamellae). Orthogonal to the individual layers, such layer lattice structures can absorb high forces, whereas the individual layers are easily displaceable in the tangential direction under the effect of force. The best-known representatives of these structurally effective solid lubricants include graphite, molybdenum disulphide (MoS2) and α-boron nitride.

A second main group of solid lubricants can be summarised under the category "solid lubricants with an active reaction". Such solid lubricants with an active reaction react under load with the material surface of the friction partners, whereby abrasion-resistant adhesive layers are formed. This type of solid lubricants includes various phosphates, carbonates, oxides and hydroxides. They are usually light-coloured or even white inorganic compounds, which is why they are sometimes declared by terms such as "light-coloured solid lubricants" or "white solid lubricants". This type of solid lubricant has proven particularly effective in preventing tribo-corrosion.

A third category of solid lubricants is usually grouped under the generic term "physically effective solid lubricants". These are ductile solids that also have low coefficients of friction. Examples of this group of solid lubricants include the metals copper, aluminium and nickel, but the organic polymer polytetrafluoroethylene (PTFE) could also be classified as a physically effective solid lubricant.

When are solid lubricants used?

Solid lubricants in greases

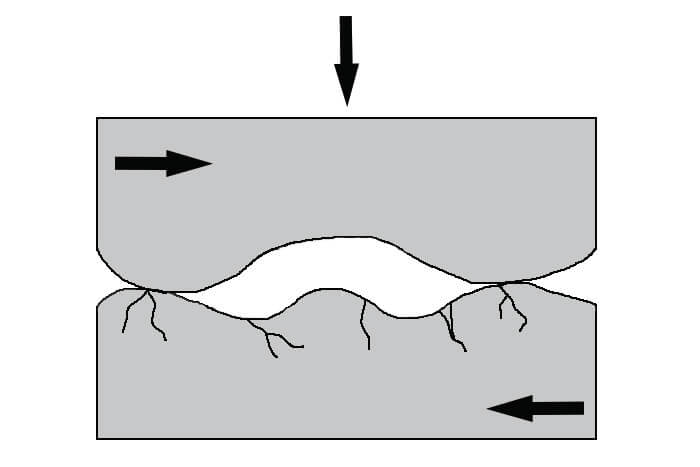

The addition of powdered solid lubricants to lubricating greases proves to be advantageous if they are used under mixed and/or boundary friction conditions. This would be the case if the friction partners involved only have low relative speeds to each other and are simultaneously under high load effects. In contrast, the use of solid lubricants in the hydrodynamic lubrication system does not make sense and is often even counterproductive. Lubricating greases containing solid lubricants are considered greases if their solid lubricant content does not exceed a maximum amount of 10%.

The lubricating greases with additives of the solid lubricant graphite include the Addinol products Mehrzweckfett L 2 G, Additemp BG 1 and Grease EP 2 G. Addinol Adhesive Lubricant OG 0 and Addinol Combiplex OG 0-2500 also contain graphite additives (the latter two lubricants are particularly suitable for the lubrication of open gears). MoS2 in pure form is used in Addinol Wear Protect RS 2 MO as a solid lubricant. For combinations of graphite and MoS2 synergistic effects could be proven several times in the past. Such combined solid lubricant mixtures of graphite and MoS2 contain Addinol Multipurpose Grease L 2 MO and Addinol Longlife Grease MG 1. Due to the inherent colouring of the added solid lubricants, all the greases mentioned here are deep black or black-grey in colour.

Light-coloured, reactive solid lubricants are contained in the products of the FG Grease AL range and in Addilith EP 2 SL.

Solid lubricants in pastes

Pastes are basically similar in structure to greases, but differ from them essentially in their significantly higher solid lubricant content, which is typically above 40%. All solid lubricant types described above can be used to produce pastes. Addinol Anti-Seize Paste 23 White, for example, is based on reactive solid lubricants, Addinol Assembly Paste HTP 700 PG is based on the structurally active solid lubricant MoS2 and Addiflon White 2 Paste Plus contains the physically active solid lubricant PTFE.

Due to the high solid lubricant content and the very good temperature resistance of some solid lubricant types, pastes can be produced whose functionality is maintained even at operating temperatures above 1000°C (hot screw pastes, high-temperature separating pastes). Addinol Chisel Paste (based on a solid lubricant combination of copper and graphite) and Addinol Anti-Seize Paste GAL (contains aluminium powder as a solid lubricant) are among these high-temperature-stable pastes.

Solid lubricants in bonded coatings

Bonded coatings contain solid lubricants in combination with a suitable binder and a solvent. After application, the solvent evaporates and a dry film containing solid lubricant remains on the application site. Two different bonded coatings in spray form are currently available in the Addinol product range: Addinol PTFE Varnish Spray (contains the solid lubricant PTFE) and Addinol TSM 401 Spray (contains the solid lubricant MoS2).

ADDINOL products with solid lubricants

Enclosed you will find an excerpt from our range of products containing solid lubricants with special properties. You will find the complete overview of greases in the Productfinder.

ADDINOL ANTI-SEIZE PASTE GAL

Application type:

High-temperature lubricant

ADDINOL Multi-purpose Grease L 2 MO

Application type:

Multi-purpose grease

ADDINOL LONGLIFE GREASE MG 1

Application type:

Heavy-duty grease

ADDINOL Adhesive lubricant OG 0

Application type:

Adhesive lubricant

Contact