ADDINOL High-performance lubricants

ADDINOL offers more than 650 high-performance lubricants for automotive and industrial applications. They are all state-of-the-art construction elements. Developed with our knowledge and in close co-operation with leading international OEMs, they are matched to the latest technologies and the requirements of our customers. Search in our product groups and find the best lubricant for your need.

Our high-performance lubricants are developed and produced in Leuna, Germany and have been offering quality "Made in Germany" since 1936.

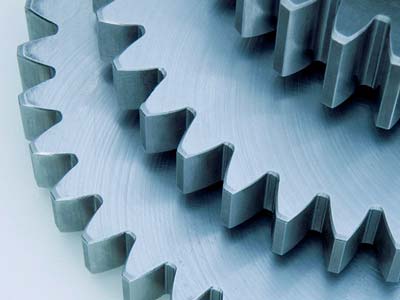

Industrial lubricants for a variety of applications

In the industrial sector, ADDINOL offers a wide range of products, from gas engine oils, industrial gear oils, chain lubricants and lubricants for food industry through turbine oils, hydraulic fluids and mould separation oils to sprays, lubricating greases and compressor oils.

Buy lubricants for your car

In the automotive sector, the product range comprises motor oils (cars, trucks and motorcycles), automotive transmission oils and function fluids, as well as universal tractor oils, automatic transmission fluids and lubricants for ships and rail vehicles.

Of course, our motor vehicle lubricants include common multi-grade engine oils in SAE grades 5w30, 10w40 or 15w40. These have been released by leading manufacturers such as BMW, VW or Mercedes.