Dropping point

The dropping point is an important quality criterion for lubricating greases. It designates the temperature in degrees Celsius at which a lubricant liquefies and begins to "drip". The dropping point is determined by means of a specific test procedure under laboratory conditions. The dropping point does not describe the highest application temperature of a lubricating grease. This should always be far below the dropping point so that the dropping point is never reached if possible.

How is the dropping point determined?

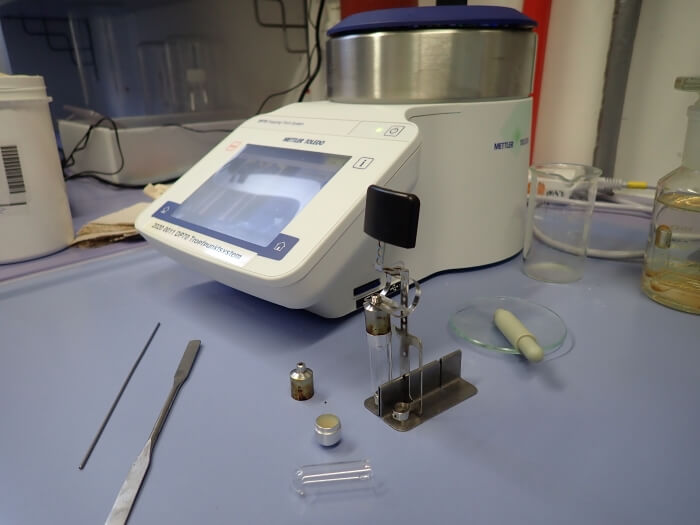

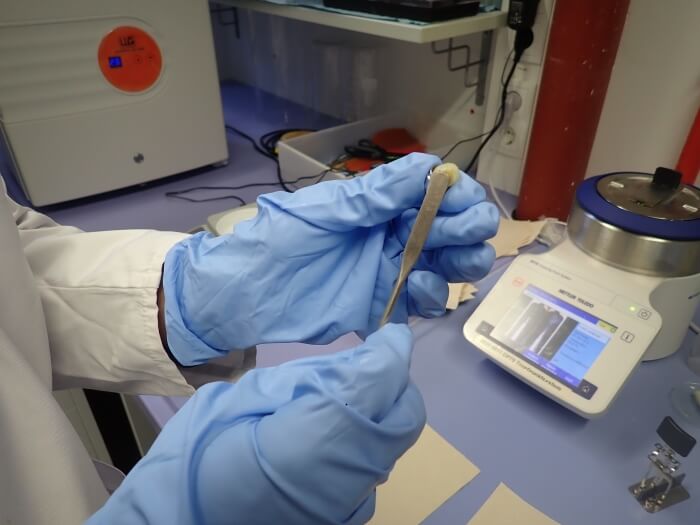

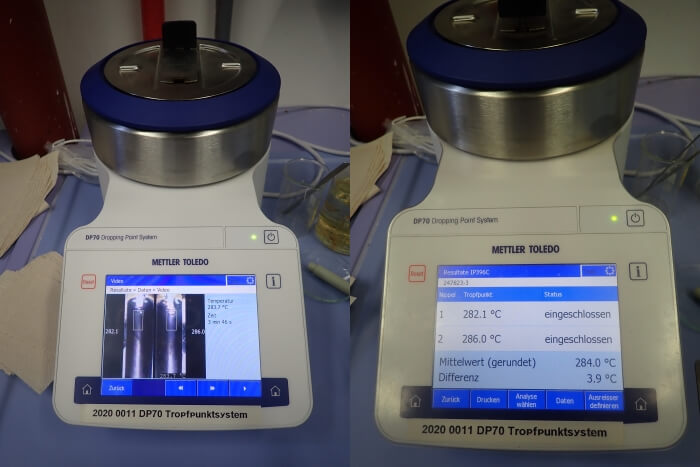

The measuring method for determining the dropping point of a lubricant is regulated in the standard DIN ISO 2176, or IP 396. Under standardised conditions, a grease sample is filled into a so-called "nipple" and heated until liquefaction starts and a drop falls through the opening of the test tube. The measured temperature at this point is called the dropping point.

Why is the dropping point relevant for a grease?

Lubricating greases are used to lubricate moving parts precisely when it is impractical to supply oil to a lubrication point. Oil can drip or run out at certain points, for example. If the lubricant does not adhere to these points and liquefies during use, there will be insufficient lubrication and inevitably damage to the machine. Therefore, it is important to observe the dripping point of a grease in order to prevent the grease from liquefying at the necessary operating temperature.

Contact