What is the cone penetration of greases?

The consistency of lubricating greases can be determined by means of a standardised measuring method like the cone penetration. The cone penetration provides some information about the viscosity of lubricating grease. The method is specified by the National Lubricating Grease Institute (NLGI). The consistency of the grease is a measure of plasticity and determines its strength and smoothness as well as its later use.

How does the cone penetration works?

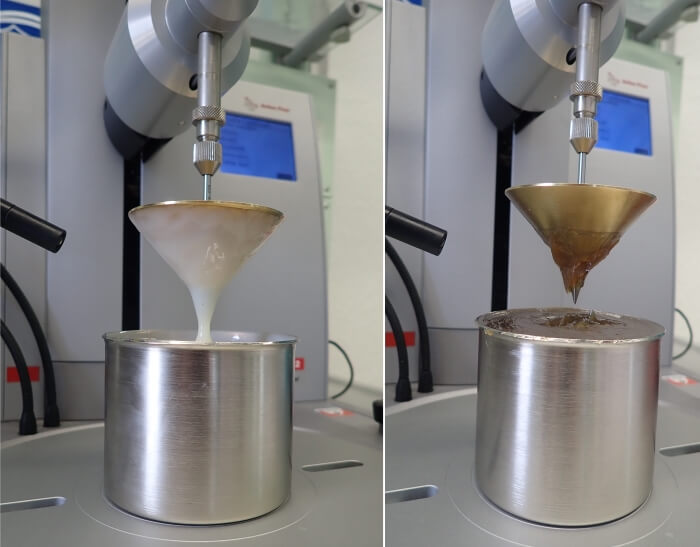

Grease consistencies are measured by cone penetration according to DIN ISO 2137. In preparation for a measurement of the cone penetration, the grease to be tested is first rolled through with the aid of a grease kneader (see picture below). The grease kneader is filled with a defined amount of grease and the screen disc in the grease kneader is then moved with 60 double strokes at 25°C through the grease contained. The grease contained in the sealed grease kneader is pressed through the holes of the sieve disc and thus subjected to a defined mechanical load.

The cone penetration is then measured using a penetrometer. For this purpose, the fat, which has been milled with 60 double strokes, is filled into a beaker at 25°C and the tip of a standardized test cone is placed on the fat surface. After loosening the test cone lock on the penetrometer, it can penetrate the grease for a period of five seconds. After these five seconds, the penetration depth of the test cone into the grease is determined with an accuracy of 0.1 mm. Equivalent to the term "cone penetration", the term "fulling penetration after 60 double strokes" is also commonly used.

Which NLGI classes are there?

Depending on the measurement result obtained, lubricating greases are divided into nine different consistency classes, the so-called NLGI classes. The assignment of a measured cone penetration to a defined NLGI class is carried out according to DIN 51818. Greases of NLGI classes 000, 00 and 0 are referred to as free-flowing greases due to their low consistency. They are often used for the lubrication of open or closed gearboxes. Greases with medium consistencies in NLGI classes 1, 2 and 3 are typical multi purpose greases for rolling bearings. Greases with higher consistencies in NLGI classes 4 and 5 or in the highest NLGI class 6 (so-called block greases) are hardly used today.

Are you interested in our greases? Find a sales partner near you.