What is viscosity?

Viscosity describes the flow behaviour of a fluid or gas. It reflects the extent of the internal friction of particles in a liquid. Viscosity is one of the most important physical characteristics of a liquid. The areas of application and possible uses of an oil are determined, among other things, by its viscosity. Nevertheless, the viscosity alone is not a quality feature of an oil. It only describes the ability to create a lubricating film between two friction partners.

Viscosity is related to the molecular structure of the fluid components. To overcome the resistance between the molecules due to the attractive forces, a certain force is required.

The term viscosity is derived from the viscous juice of the mistletoe berry (Latin: viscum). This juice is as thick and sticky as glue. The liquid was used to catch birds.

Viscosity Units and Formulas

To calculate the viscosity of a fluid, a distinction is made between dynamic and kinematic viscosity. Dynamic viscosity is the ratio of shear stress and velocity gradient vertically to the direction of flow. This is also referred to as "flow resistance within a liquid". The kinematic viscosity results from the ratio of the dynamic viscosity and the density.

| Dynamic viscosity | Kinematic viscosity | |

|---|---|---|

| Formula symbols | η | ν |

| Unit | Pa·s | mm²/s |

The viscosity of a liquid can be measured according to ISO 3219 using a viscometer. The second possibility would be to measure with a rheometer.

With lubricating greases, in contrast to oils, it is not the viscosity but the consistency that is determined. This is done, for example, by measuring methods such as cone penetration.

Examples of viscosity

Typical fluids and their viscosity values are presented below. This allows the classification of the different substances.

| Fluid | η in mPa·s |

| Water at 20 °C | 1.0 |

| Water at 25 °C | 0.891 |

| Water at 5 °C | 1.52 |

| Mercury at 20 °C | 1.55 |

| Ethanol at 20 °C | 1.19 |

| Petrol at 40 °C | approx. 0.5 |

| Diesel at 40 °C | approx. 3.1 |

| Engine oil at 25 °C | approx. 100 |

| Engine oil at 150 °C | approx. 3 |

| Heating oil at 20 °C | approx. 4-6 |

| Bitumen at 20 °C | approx. 1011 |

| Olive oil at 20 °C | approx. 10² |

| Honey at 20 °C | approx. 104 |

| Blood at 37 °C | approx. 4-25 |

Temperature dependence of viscosity

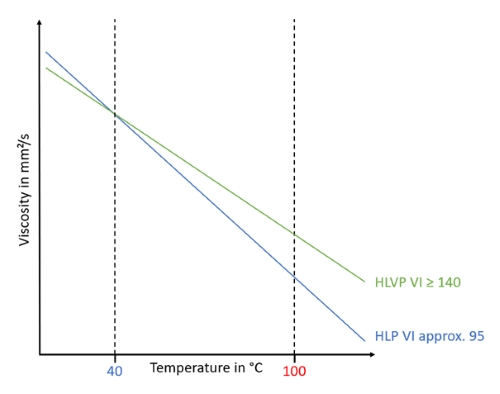

The viscosity of a liquid always depends on the temperature. The dynamic viscosity of a liquid decreases with increasing temperature. The dynamic viscosity increases with decreasing temperature. A liquid becomes less viscous (thinner) when heated and it becomes more viscous (thicker) when it gets cold. For oils, the viscosity index determines the relation between kinematic viscosity and temperature. The viscosity of the oils always depends on the temperature. However, the degree of temperature dependence is determined by the quality of the oil. The viscosity-temperature behaviour of oils is quite complex because it does not develop linearly with temperature. Each type of oil shows a different behaviour. Two oils, for example, can have the same flow behaviour at 40 °C, but can have completely different viscosities at 100 °C.

Viscosity index

The viscosity index (VI) is the behaviour of the lubricant as a function of temperature. It refers to the kinematic viscosity of an oil. The viscosity behaviour at 40 °C and 100 °C is measured. To a certain extent, the viscosity index is also an indication of the quality of an oil and serves the comparability of different oil types. Oil with a high viscosity index is less temperature dependent. The oil retains its lubricating properties in a wider temperature range. The oils with a low viscosity index can be influenced more strongly by the temperature. Their lubricating properties become unstable at high or low temperatures. When the viscosity index was developed in 1928, the scale was based on the mineral oil types known at the time. The viscosity index started at 0 (very temperature-dependent oils) and went up to 100 (oils with low temperature dependence). In the meantime, the scale has reached values of up to 400, due in part to modern production processes for temperature-stable synthetic oils. In addition, the viscosity index of oils can be artificially increased by adding high-performance additives (VI improvers).

| Oil type | VI |

| Mineral oil | 80-120 |

| HC oil | 120-140 |

| PAO oil | 135-160 |

| Esters | 140-190 |

| Glycol | 200-220 |

The different behaviour of oils can be represented graphically by means of a viscosity-temperature diagram (VT diagram). Through mathematical transformation, the VT behaviour can be represented by means of a straight line through the important measuring points of 40 °C and 100 °C. The VT behaviour can be represented by a mathematical transformation, which can be visualized in a diagram. This makes it possible to see which oils are suitable for certain operating temperatures and applications.

Pressure dependence of viscosity

In addition to temperature, the viscosity of oil also depends on pressure. In comparison, however, this dependency is low. The viscosity increases with increasing pressure, i.e. the oil becomes more viscous. The viscosity-pressure behaviour is only of importance from a high pressure of more than 400 bar. At a pressure of less than 400 bar, the viscosity changes are only marginal. To better classify the low relevance of pressure to viscosity, it can be stated that a pressure increase of 100 bar has less influence on the oil viscosity than a temperature increase of 10 °C. A further phenomenon in this context is that the increase in pressure (oil becomes more viscous) is accompanied by an increase in temperature, which makes the oil more viscous again. Accordingly, the viscosity-pressure behaviour is also influenced to a certain extent by the viscosity-temperature behaviour.

Viscosity changes of oil in use

Not only does oil change its viscosity due to temperature influences and pressure, but the environmental influences during operation can also have a lasting effect on the flow properties. If the viscosity of the oil deviates greatly from the initial values of the fresh oil, this is an indication that accelerated oil aging has occurred. If this happens the oil should be changed. The viscosity of the oil can either increase or decrease. Both cases are not desired because the oil no longer optimally fulfils the required lubricating properties for the application.

Causes for the increase in viscosity are:

- Oxidation (oxygen input into the oil), degradation of oxidation inhibitors (additives)

- Acidification

- Varnish formation (varnish and sludge formation)

- Contamination by foreign substances (combustion residues, water)

- Use of the wrong oil (e.g. for refilling)

Causes for a decrease in viscosity are:

- Degradation of VI improvers (additives)

- Fuel input into oil (oil dilution)

- Use of the wrong oil (e.g. for refilling)

Viscosity classes of oil

Lubricants used in the automotive and industrial sectors are divided into special classes in order to classify them better and to apply them in line with requirements. Viscosities can be classified using comparable test parameters.

We distinguish:

SAE classes for engine oils and gear oils

SAE stands for Society of Automotive Engineers. This organization publishes the worldwide classification for viscosity classes in the field of engine oils and automotive transmission oils. There are significant differences in the types of oil.

Engine oils can be classified as singlegrade or multigrade oils. In the case of multigrade oils, the properties of the oils are characterized by winter and summer suitability. A multigrade oil lubricates optimally during cold starts in winter and summer and ensures a load-bearing, separating lubricating film at operating temperature (100 °C). Therefore, the kinematic viscosity of engine oils is determined at 100 °C. An example is the widely used multigrade oil 5W30. In contrast, monograde oils such as SAE 30 fulfil only one of the properties.

Engine oils are classified according to the SAE J300 specification. Classic engine oils such as the 5W30 or the 0W40 require a basic oil with a high viscosity index. VI improvers are added during production.

| SAE class | Low temperature Viscosity in mPa·s | Borderline pumping temperature in °C 1) | Min. low-shear rate at 100 °C in mm²/s | Max. Low-shear rate at 100 °C in mm²/s | HTHS 150 °C in Pa·s |

|---|---|---|---|---|---|

| 0W | 6.200 | -40 | 3.8 | - | - |

| 5W | 6.600 | -35 | 3.8 | - | - |

| 10W | 7.000 | -30 | 4.1 | - | - |

| 15W | 7.000 | -25 | 5.6 | - | - |

| 20W | 9.500 | -20 | 5.6 | - | - |

| 25W | 13.000 | -15 | 9.3 | - | - |

| 8 | - | - | 4.0 | < 6.1 | 1.7 |

| 12 | - | - | 5.0 | < 7.1 | 2.0 |

| 16 | - | - | 6.1 | < 8.2 | 2.3 |

| 20 | - | - | 6.9 | < 9.3 | 2.6 |

| 30 | - | - | 9.3 | < 12.5 | 2.9 |

| 40 | - | - | 12.5 | < 16.3 | 2.9 2) |

| 40 | - | - | 12.5 | < 16.3 | 3.7 3) |

| 50 | - | - | 16.3 | < 21.9 | 3.7 |

| 60 | - | - | 21.9 | < 26.1 | 3.7 |

1) The cold start safety is approx. 5 °C above the borderline pumping temperature.

2) The HTHS value applies to the multigrade oils 0W/5W/10W-40.

3) The HTHS value applies to multigrade oils 15W/20W/25W-40.

Some modern high-performance engines require a minimum oil viscosity at an operating temperature of 150 °C and a shear rate of 106/s. This is called HTHS viscosity (High Temperature High Share). This limit value ensures that the engine oils fulfil the necessary lubricating properties at high temperatures and high speeds (shear rate). The limit values were determined by institutes such as SAE or ACEA as well as by some automobile manufacturers.

Gear oils are classified according to the SAE J306 standard.

| SAE class | Low temperature viscosity at 150.000 mPa·s in °C | Min. viscosity at 100 °C in mm²/s | Max. viscosity at 100 °C in mm²/s |

|---|---|---|---|

| 70W | -55 | 3.8 | - |

| 75W | -40 | 3.8 | - |

| 80W | -26 | 8.5 | - |

| 85W | -12 | 11.0 | - |

| 65 | - | 3.8 | < 5.0 |

| 70 | - | 5.0 | < 6.5 |

| 75 | - | 6.5 | < 8.5 |

| 80 | - | 8.5 | < 11.0 |

| 85 | - | 11.0 | < 13.5 |

| 90 | - | 13.5 | < 18.5 |

| 110 | - | 18.5 | < 24.0 |

| 140 | - | 24.0 | < 32.5 |

| 190 | - | 32.5 | < 41.0 |

| 250 | - | 41.0 | - |

ISO VG classes for industrial lubricating oils

ISO VG means "International Organization for Standardization Viscosity Grade". In the 18 viscosity classes, a minimum and maximum kinematic viscosity is defined in which the lubricants are allowed to flow at 40 °C. This is the minimum and maximum kinematic viscosity. The classes range from 2 (very thin) to 1500 (very thick).

| ISO VG | Center viscosity in mm²/s at 40°C | Kin. viscosity min. in mm²/s at 40°C | Kin. viscosity max. in mm²/s at 40°C |

|---|---|---|---|

| 2 | 2.2 | 1.98 | 2.42 |

| 3 | 3.2 | 2.88 | 3.52 |

| 5 | 4.6 | 4.14 | 5.06 |

| 7 | 6.8 | 6.12 | 7.48 |

| 10 | 10 | 9 | 11 |

| 15 | 15 | 13.5 | 16.5 |

| 22 | 22 | 19.8 | 24.2 |

| 32 | 32 | 28.8 | 35.2 |

| 46 | 46 | 41.4 | 50.6 |

| 68 | 68 | 61.2 | 74.8 |

| 100 | 100 | 90 | 110 |

| 150 | 150 | 135 | 165 |

| 220 | 220 | 198 | 242 |

| 320 | 320 | 288 | 352 |

| 460 | 460 | 414 | 506 |

| 680 | 680 | 612 | 748 |

| 1000 | 1000 | 900 | 1100 |

| 1500 | 1500 | 1350 | 1650 |

Since the three viscosity classes are evaluated according to different parameters, the classes can only be compared to a limited extent. The comparative tables that are established so far have been classified very roughly and cannot be evaluated as scientifically correct. Please use only lubricants that are recommended by the manufacturer and do not rely on approximate specifications.

Contact