Plain bearing lubrication

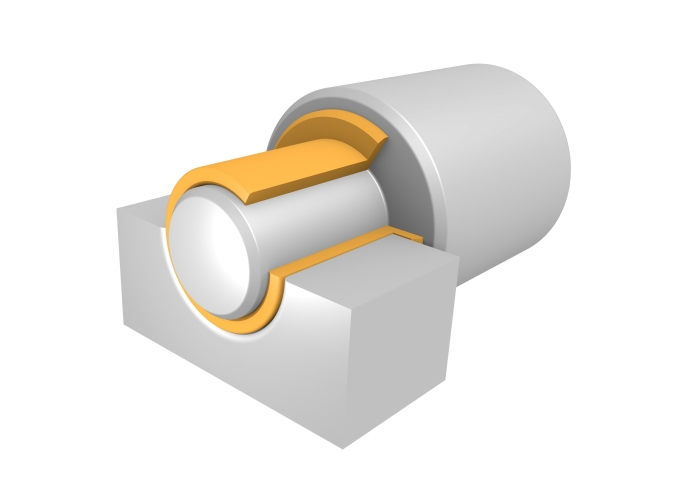

In a plain bearing, bearings and guides hold engine and machine parts that are moving relative to each other in firmly defined paths. In the process, the forces that occur are transmitted. The sliding partners must be separated by a lubricant to prevent wear.

There are various forms of plain bearings. They differ, for example, according to the load direction. In radial bearings, the load moves radially to the axis of rotation. In an axial bearing, the load moves parallel to the axis of rotation. Axial-radial bearings represent a mixed form of these. The type of lubrication is also decisive for plain bearings. Typical types are, for example, hydrostatic and hydrodynamic lubrication.

Which lubricant is suitable for plain bearings?

The lubricant must ensure the lowest possible friction loss during operation. Therefore, the viscosity of the lubricant in operation is decisive. However, the viscosity required for your system depends entirely on the design (e.g. rotational speed) and the environmental conditions (e.g. temperature, dirt ingress). Please consult our application technology department for individual advice. The following properties are typical for all lubricants used in plain bearings: good adhesion, low foaming tendency, no emulsion formation with water, ageing protection and corrosion protection.

For the lubrication of plain bearings, oils, greases, solids or gases can be used. Our multi-purpose greases are a in most cases suitable for plain bearing lubrication. They have already proven themselves many times in various systems.

Contact