How is tribology defined?

Tribology is also referred to as the science of friction. It describes the science of surfaces acting on each other in relative movements. Typical elements of tribology are friction, wear and lubrication. Tribology considers the interactions between different solids and also the interaction between solids and liquids or gases.

Types of friction

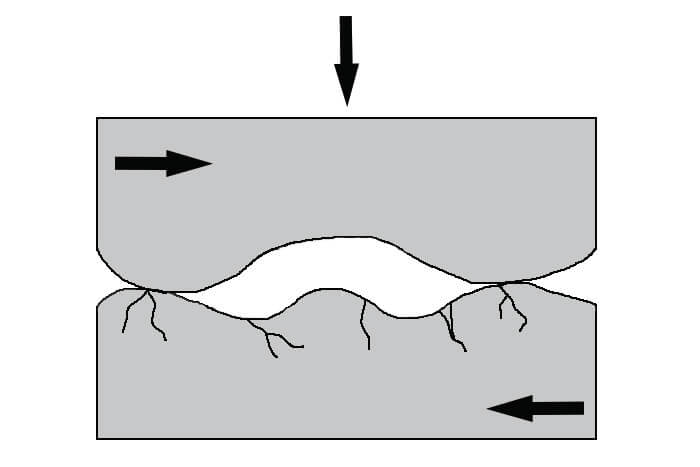

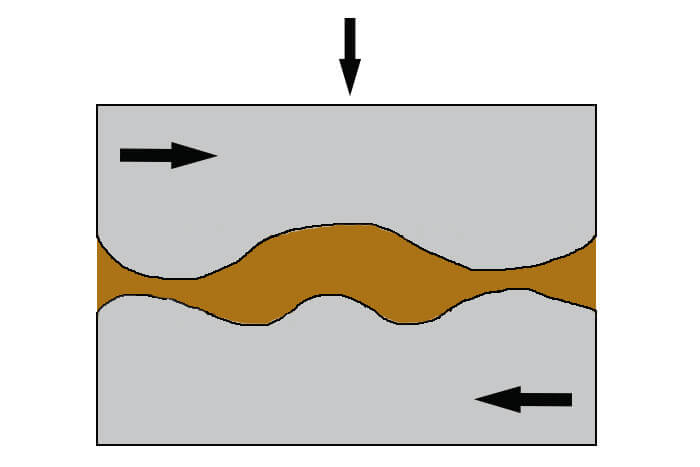

In tribology, friction describes the sum of the forces that arise at the contact surface of two bodies and influence their movement against each other. The frictional force is influenced by other factors, too. These include, for example, the load with which the surfaces are pressed against each other, the operating temperature, the speed of movement or the roughness of the material surfaces. Because no matter how smooth a surface appears, if you look at it under a microscope, the smallest irregularities in the material become visible. Without some form of separation, e.g., by a lubricating film, these surface irregularities can seize up on contact. In any case, some abrasion, adhesion and/or flaking of these irregularities takes place during movement.

There are different types of friction. The types are classified according to the type of movement, the condition at the interfaces and the sliding speed. These types are:

- Dry friction: Describes the friction between two surfaces without a liquid film, gases or other contamination.

- Boundary friction: Is the friction between two surfaces separated by oxides, liquids or other impurities.

- Lubricated or fluid friction: Here, the friction partners are completely separated from each other by a layer of liquid or gas in order to minimise wear. A distinction is made between hydrostatic and hydrodynamic friction.

- Mixed friction: Is a mix of boundary and lubricated friction.

The challenge is to reduce the coefficient of friction as much as possible by either eliminating or at least controlling the factors that can negatively affect the surface in relative motion.

There are several ways to reduce friction in mechanical systems:

- Use of lubricants whose viscosity and composition have been matched to the application. A special additivation can optimise an oil for each application. In some cases, solid lubricants such as graphite are also suitable.

- The use of surfaces that can compensate for abrasion, such as materials with low shear strength, of which lead/copper plain bearings are an example.

- Replacing sliding friction with rolling friction, e.g., by using roller bearings.

Wear is the unwanted change in the shape and properties of a material surface due to external influences. There are mechanical (contact with other surfaces), thermal (heat or cold), chemical (corrosion) or electrical influences that can cause wear. In lubrication technology, wear is mostly caused by mechanical factors (in the form of abrasion or material chipping) in which two bodies move against each other.

A distinction is made between different forms of wear. These include abrasive wear, adhesive wear, surface disruption and tribo-oxidation.

In the case of metallic surfaces, the damage patterns pitting or micropitting often occur.

Contact