Do electric cars need oil?

The question can definitely be answered with yes. Although the requirements for lubricants will change in part, electric cars will continue to need oil. This applies, for example, to components such as transmissions, wheel bearings and air conditioning systems.

However, the classic engine oil used in combustion engines is no longer used in electric cars. Since the axles in electric cars are supplied with energy and driven by a battery, the moving parts that a combustion engine needs for propulsion, such as pistons and cylinders, are no longer needed. In the electric engine there are no friction partners that require lubrication.

What are the lubrication points on electric cars?

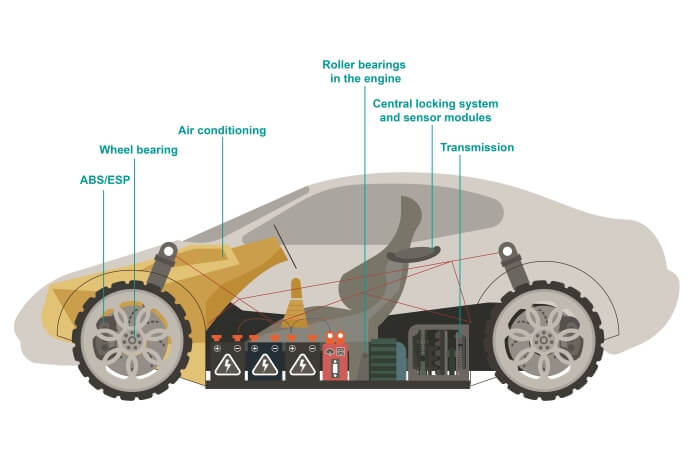

In an electric car, there are still some components that require lubricants. These include:

- Transmissions

- Central locking and other sensor motors

- Roller bearings in the electric engine

- Air conditioning

- Wheel bearing

- ABS/ESP

Comparison of lubrication points in electric cars, hybrid cars and cars with combustion engines

In the following table we list important lubricants for cars and briefly summarise whether the lubricant is still needed and if so, with any special features. The types electric engine, hybrid engine and combustion engine are compared.

| Lubricant | Combustion engine | Hybrid engine | Electric engine |

| Engine oil | Is needed | Is required, depending on the construction multi-grade oil or 4-stroke oil is required | Not required |

| Transmission oil | Is needed | Is needed | Is needed, with new requirements |

| Greases | Is needed | Is needed | Is needed, with new requirements |

| Hydraulic oil | Is needed | Is needed | Is needed |

| Functional fluids such as coolant, brake fluid etc. | Is needed | Is needed | Is needed, to an increased extent |

How does oil for electric cars differ from oil for cars with combustion engines?

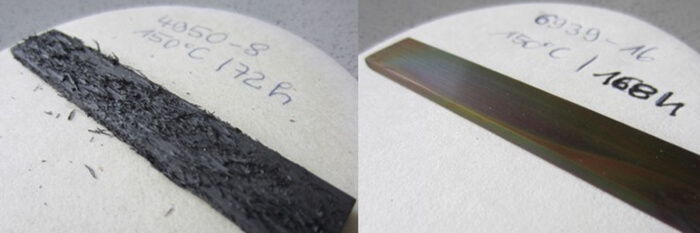

The different construction of electric cars compared to cars with combustion engines inevitably results in different requirements on the lubricants. Therefore, special lubricants for electric cars have to be developed.

Lubricants for electric cars must have the following properties:

- Dielectric properties for lubricants in direct contact with electrical components to prevent short circuits and sparks

- Compatibility with various materials such as copper (high electrical conductivity) and polymeric cable sheathing

- Cooling properties due to good heat dissipation of the electrical energy

- Wear, oxidation and corrosion protection for the entire system

- Strict water separation to prevent electrical flashovers between live components

There are currently no general approvals and specifications for lubricants in electric cars. The different construction methods of electric vehicles make standardisation even more difficult. Therefore, the current lubricants for electric cars are individually adapted to specific applications.

The most important lubrication points in electric cars

In electric cars, the transmission works largely without gear shifting and is only single or two-stage. In the transmission of electric cars, very high speeds can occur at times, resulting in increased thermal and physical stress on the oil. The transmission oil for electric cars requires high heat resistance and robustness.

Lubricating greases are used in the electric engine, in auxiliary units and in the central locking system. They must withstand harsh conditions in the electric car and absorb high temperatures and rotational speeds in the roller bearing of the electric engine. At the same time the greases must be compatible with many materials such as copper, plastics and electronic components.

To keep the batteries in the electric car functional, a good cooling system is essential. Media such as air and water are hardly sufficient for cooling. For this reason, the first cooling liquids for electric cars are currently being developed, which are designed for the special construction of the battery cells.

Research contract for lubricant manufacturers

As a lubricant producer ADDINOL faces the new challenges of electric mobility and works out solutions. The increased demand for electric cars is thus taken into account. Even if currently only few electric cars hit the road, the number of first registrations will increase in the coming years. Especially in cities, an increase in the number of electric cars is expected if the number of charging stations is adjusted in time. If the emission-free cars are currently mainly used for short distances, manufacturers will work on increasing the range of the batteries and reducing charging times. Once electric cars with a range of 600-800 kilometres can be produced and charging takes only a few minutes, electric cars will be indispensable. Lubricant manufacturers will also contribute to this development. Efficient and individually formulated lubricants can improve the performance of electric cars by optimising power transmission, resisting heat and cooling key components. The first products of ADDINOL for electric mobiles are already in planning.