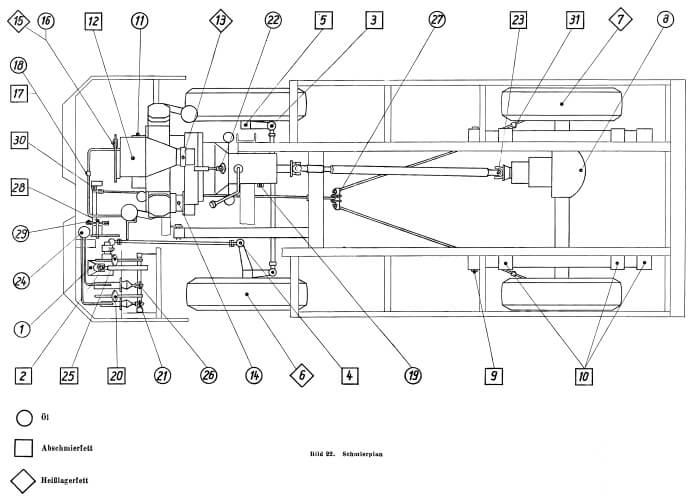

Lubrication plan

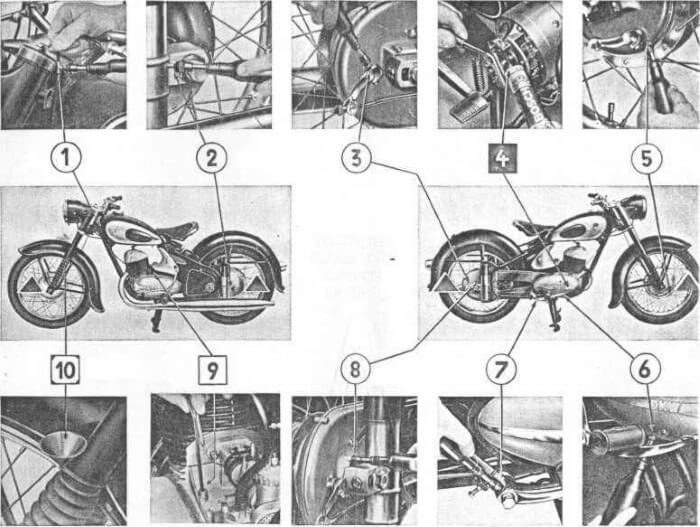

A lubrication plan defines all lubrication instructions for a specific machine or system, including lubrication point designations, lubricant types, lubricant quantities and maintenance intervals. The lubricants are described by approvals or specifications. In some cases, specific products are also prescribed for the lubrication points. A lubrication plan is an essential part of the maintenance of technical equipment. In order to identify the lubrication points, it is advisable to draw sketches or take photos. This simplifies maintenance if such plans do not already exist.

What should be considered in a lubrication plan?

Each machine has a clearly defined lubrication plan. However, different lubricants may be needed in different situations. Depending on the stress, intended use or environmental influences, different problems can occur which require optimised lubricants. The ADDINOL application technology will be pleased to check your plant and can e.g. point out and correct possible problems with an oil analysis. We also support you in the selection of lubricants and the determination of change intervals with analytical assistance.

Of course, you should first follow the manufacturer's instructions for maintaining a lubrication plan. Certain subtleties need to be optimised during operation. For example, the time until the next oil change can vary depending on the temperature at the production site. Is it worthwhile to lubricate certain lubrication points automatically or manually? How often do the lubrication points need to be inspected or checked for contamination? There are many questions we can help you with. Please feel free to contact us.

Contact