ADDINOL Cliptec XHS series for film stretching lines

Lubricants are not just oils and greases, particularly in applications in the film stretching industry - they are construction elements and are primarily responsible for the consistent functionality of the system!

Non-stop operation with nearly than 8,000 hours per year, always high speeds and increased temperatures – ADDINOL high-performance high-speed chain oils of the Cliptec XHS series are perfectly fit for such extreme requirements typical of modern film stretching lines. They ensure a safe and reliable lubrication of all components and a trouble-free operation of the plants. On top of that, they are highly efficient lubrication tools for cutting operating as well as maintenance costs and increasing plant efficiency.

In spite of high process temperatures, the high-speed chain oils of the ADDINOL Cliptec XHS series do not form any lacquers or encrustations on slide surfaces, chain tracks or bolts. Lubrication pipes remain free of any obstruction.

Your practical benefits

Approved by Brückner, DMT and Andritz

Our oils are also recommended by Mitsubishi and many other OEMs. The Addinol Cliptec XHS series chain oils have been developed, tested and approved with Brückner for the use in BOPP and BOPET film stretching lines. The products of the Cliptec XHS series are compatible with all plastics of the film processing technology and guarantee unrestricted production stability and safety.

Chain Oil

ADDINOL Cliptec XHS chain oils on ester basis were specifically and developed exclusively for high-speed chain track systems especially for film stretching lines.

High Temperatures

The moistening and lubrication of sliding and rolling contacts on chain links, bolts and clamps is optimally and always guaranteed even at high temperatures (for applications up to +260°C).

Up to maximum speeds

The ADDINOL Cliptec XHS series offers the right product for any chain speed. Even at high speeds no dripping and spinning off and thus no contamination of the film.

Addinol food safe chain oils for BOPP and BOPET lines

Fulfils all requirements that are prescribed for safe use in the food and packaging industry: Cliptec XHS 485 FG and Cliptec XHS 285 FG according to NSF H1 and Cliptec XHS 480 and XHS 280 according to NSF H2 registered. The Cliptec XHS 485 FG and 285 FG are also kosher and halal certified.

Manufactured exclusively in Germany and continuously checked in a certified production line.

|  |  |

More advantages of the ADDINOL Cliptec XHS series

- Low oil consumption: The extremely low evaporation loss results in lower oil consumption.

- High efficiency: Due to its powerful additives the ADDINOL Cliptec XHS series shows an optimum friction behaviour which reduces thermal and mechanical stress, increases efficiency and allows higher speeds.

- Less deposits: High-quality oxidation-resistant base oils reduce the tendency to form encrustations and crackings. Less residues mean less cleaning effort and ensure optimum lubrication performance.

Tailor-made for all speeds and high-speed chain applications - Made in Germany

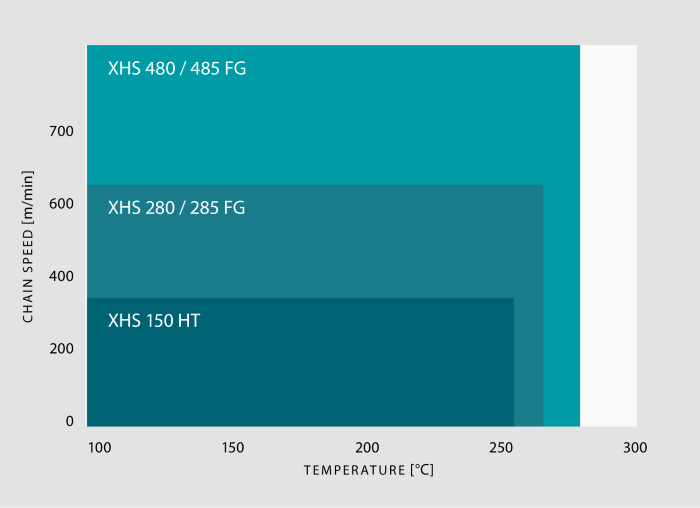

The ADDINOL Cliptec XHS series guarantees a continuous stable lubricating film for all different various applications and chain speeds at the film stretching industry applications.

In the following graphic you can see that Addinol can offer the right Addinol high speed chain oil for every type of film stretching application and every speed. I would be happy to provide you with personal advice and product recommendations.

Additional service tip: ADDINOL Chain System Cleaner HT

Addinol Chain System Cleaner series is a preventive and a really helpful maintenance tool. With regular application ADDINOL Chain System Cleaner HT/FG is able to minimises the maintenance total effort of the cleaning process, reduces annual maintenance costs and allows a trouble-free operation between the scheduled maintenance intervals prescribed by the OEM.

Especially developed for an additional cleaning and protecting of the entire chain track lubrication system and bolt lubrication system as well.

Recommended for BRÜCKNER film stretching lines

- As part of general maintenance and repair

- When commissioning a new plant

- For optimum preparation when changing to a high performance chain lubricant of the ADDINOL Cliptec XHS series

Danilo Förster

Technical Sales Manager, Head of the Business Unit Film Stretching Lines