Lubricants for wind power plants by ADDINOL

The ADDINOL gear oils of the Eco Gear series have already proven themselves many times in the application in wind power plants. They optimally lubricate both pre-damaged and freshly installed gears.

In pre-damaged gears showing clear traces of wear, material erosion or chipping, the ADDINOL Eco Gear series achieves the reliable smoothing and long-term stabilisation of the tooth flanks thanks to the PD effect (plastic deformation).

In systems without damage, the ADDINOL Eco Gear series ensures effective protection against wear, material erosion, pitting and fatigue thanks to its above-average seizure and micro-pitting resistance.

The advantages of ADDINOL Eco Gear at a glance:

| Ideal for high loads in hardened and tempered-ground gears with a tendency to micro-pitting |

| Longer than average operating intervals |

| Minimal effort for maintenance and oil change-related downtimes |

| Reliable protection against corrosion |

| Compatible with all sealing materials and lacquers |

| Free from VI improvers |

All-round care thanks to ADDINOL

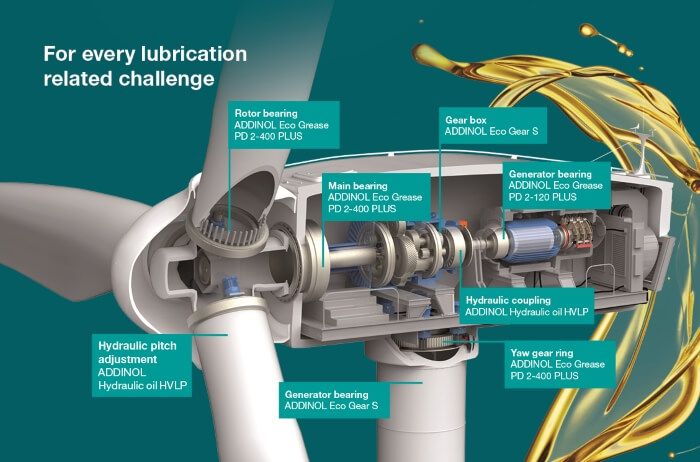

ADDINOL lubricants not only protect the gearboxes of wind turbines. Our range offers solutions for several lubrication points. The ADDINOL range also offers the right lubricants for hydraulic units and bearings, perfectly matched to the highest demands and extreme operating conditions.

The ADDINOL hydraulic oils HVLP 15 ... 46 and Ökosynth HEES 32 and 46 ensure the precise and smooth operation of the hydraulic units at the actuators and couplings of the wind turbine. Thanks to their stable viscosity index, they ensure the safe transmission of braking forces and allow precise control. They have excellent VT behaviour and guarantee optimum flowability even at low temperatures thanks to the low pour point.

The high-performance greases ADDINOL Eco Grease PD 2-220 Plus as well as PD 2-400 Plus and Combiplex OG 05 complete the high-performance range for wind power plants and are optimally equipped for high loads and temperatures. They reliably protect the various bearings of a wind turbine against wear and corrosion.

On the safe side with our analysis service

Use our oil analysis service to keep a constant eye on the development of your wind power plant. The oil analyses are first carried out in a recognised and independent laboratory. Subsequently, the oil characteristics are evaluated by engineers of the ADDINOL application technology. Finally, you receive a clear evaluation in the proven ADDILAB design with concrete recommendations for action.

Enjoy the benefits of the analysis service:

- Long-term condition monitoring of the oil and the system

- Early detection of faults and damage

- Determination of the individual oil application time for the respective system

- Maximum oil service life according to OEM specifications

- Better planning of maintenance measures and oil change-related downtimes

- Reliable operation

Contact

Volker Maiwald

Sales Germany